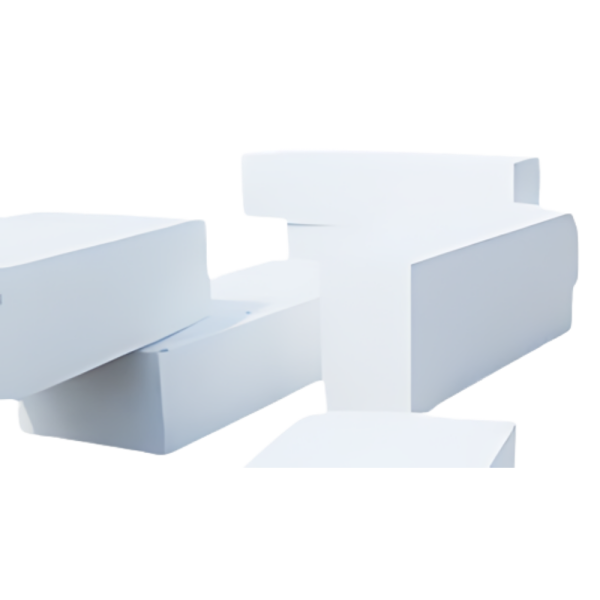

Product Overview

DADCO Polystyrene (EPS) provides superior thermal insulation for construction, industrial, and packaging applications. Manufactured as expanded polystyrene foam boards, this lightweight material offers excellent insulation properties, dimensional stability, and resistance to moisture and chemicals.

Applications

- Roof and Wall Insulation: Thermal barriers for buildings

- Foundation Insulation: Below-grade thermal protection

- Floor Insulation: Under-slab thermal barriers

- HVAC Systems: Ductwork and equipment insulation

- Cold Storage: Temperature-controlled environments

- Packaging: Protective packaging for sensitive materials

- Construction Formwork: Temporary construction applications

Key Benefits

- Excellent Thermal Performance: Low thermal conductivity

- Lightweight: Easy handling and installation

- Moisture Resistant: Closed-cell structure prevents water absorption

- Chemical Resistant: Resistant to most chemicals and solvents

- Fire Resistant: Meets fire safety standards

- Cost-Effective: Economical insulation solution

- Durable: Long-term performance and stability

Technical Specifications

Available Densities: 16, 20, 25, 30-35 kg/m³

Physical Properties:

- Thermal Conductivity: 33-37 to 31-36 W/mK at 10°C (DIN 53420)

- Stress at 10% Compression: 6-10 to 18-25 N/cm² (DIN 53421)

- Max. Prolonged Stress: 1.2-2.5 to 3.5-6.1 N/cm²

- Shear Strength: 43-52 to 83-118 N/cm² (DIN 53427)

- Flexural Strength: 16-21 to 31-39 N/cm² (DIN 53423)

- Tensile Strength: 16-23 to 36-51 N/cm² (DIN 53571)

Temperature Performance:

- Deformation Temperature: Stable across temperature ranges

- Short-term Load: 100% capacity (DIN 53424)

- Long-term Load at 5 kPa: 85% capacity (DIN 18164)

- Long-term Load at 20 kPa: 75-80 to 80-85% capacity (DIN 18164)

Other Properties:

- Diffusion Resistance Factor: 30-50 to 60-80

- Dimensional Stability: Excellent long-term performance

Standard Dimensions

- Thickness: 14, 16, 20, 26, 30, 33 mm (other thicknesses available)

- Length: 2 meters

- Width: 1 meter

- Custom Sizes: Available upon request

Installation Guidelines

- Clean, dry surface preparation required

- Proper mechanical fastening or adhesive application

- Vapor barrier considerations for specific applications

- Professional installation recommended for optimal performance

Quality Standards

- DIN 53420 – Thermal conductivity testing

- DIN 53421 – Compression strength

- DIN 53427 – Shear strength testing

- DIN 53423 – Flexural strength

- DIN 53571 – Tensile strength

- DIN 18164 – Long-term load performance

Certifications

- IAF Certified manufacturing

- ULF Compliance international standards

- ISO Certified quality systems

- SASO Quality Mark Saudi compliance

- Saudi Made local manufacturing

Environmental Considerations

- CFC-free manufacturing process

- Recyclable material

- Low environmental impact

- Energy-efficient production

Reviews

There are no reviews yet.